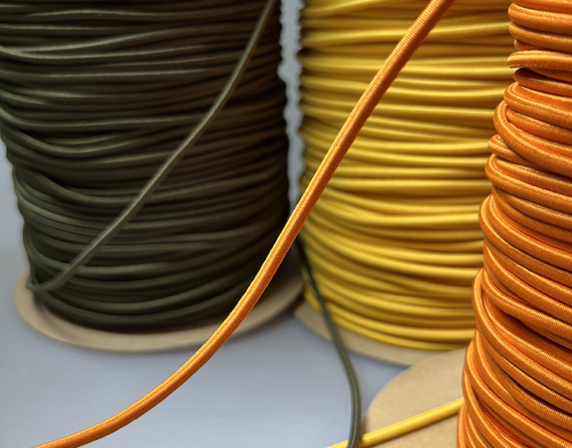

Braided elastics

In our braiding department, we manufacture both round and flat braided elastics. The important parameters of braided elastics, such as stretchiness, width, thickness, and color, can be customized according to the customer’s requirements.

Our technologists are ready to develop a completely new product according to the specifications provided. The primary application area for braided elastics is in garment and home textile sewing.

Braiding technology currently doesn’t allow for weaving logos directly into the elastics, but we can offer various color combinations to create lighter patterns. With various color combinations available, customers can create a distinctive product.

The materials available include synthetic and natural options such as polyester and various rubber threads. The possible width range for flat braided elastic bands is 4 mm to 15 mm, and for round elastic cords, it’s 1 mm to 8 mm. We offer cutting services as well as water repellent and flame retardant treatments.

We produce 100% of our products in-house

A wide selection of materials

We are very demanding in the selection of suppliers and materials. We use only the highest quality raw materials that have Oeko-Tex Standard 100 certificates. The quality of the materials directly affects the quality of our production, and as a result, we cannot make concessions here.

Our material selection includes polyester, polyamide, polypropylene, fire-resistant meta-aramid, cotton, linen, wool, various rubber threads and metallic threads. According to the product and the area of use of the product, we recommend the most suitable material to the customer. There is a sufficient range of colors for all materials to offer a suitable shade for every customer.

Available post-processing treatments

Cutting

Cutting allows the ribbon to be cut to a specific length, thanks to which the customer receives the product in a cut and packaged form.

Water resistance

The water repellency treatment ensures that the laces do not get wet.

Flame resistance

According to the field of the product, products are needed that would not catch fire. The flame retardant treatment helps to achieve the desired result.

Impregantion

As a result of impregnation, the ribbon becomes stiffer and is no longer in a soft state.

We help in the development of a new product

In cooperation with our own technologists, production managers and designers, we are able to develop products that meet customer expectations and even the most complex demands. We can offer products that require printing, cutting, special treatments (water repellency, waxing, flame resistance), laser cutting, and sewing services.

We are ready to help our customers with product development from the idea to the final product!